We are trusted Fasteners Manufacturer in India Since 1978

National Fasteners began its journey in 1978 with a single machine and a small room, founded by Mr. Gurjeet Singh. From these humble beginnings, we have grown into one of India’s leading manufacturers and suppliers of high-performance critical fasteners. Under the visionary leadership of our Managing Director, Mr. Sarabjeet Singh, we remain committed to being a reliable and trusted supplier of premium-quality fasteners from India to the world.

Over the decades, National Fasteners has expanded its reach globally, supplying a wide range of industrial fasteners to clients across multiple sectors. Today, we operate out of a state-of-the-art 25,000 sq. ft. facility, equipped with an installed production capacity of 550 metric tons of fasteners per month. Our dedicated team of over 150 skilled professionals works across two shifts to ensure consistent quality and timely delivery.

With an ambitious goal of reaching $50 million in annual revenue within the next five years, we continue to invest in innovation, infrastructure, and customer satisfaction. At National Fasteners, we are proud to be a globally trusted partner for precision fasteners made in India.

Our Quality Fasteners

Fasteners Manufacturers, Suppliers, Exporters in IndiaOur modern manufacturing capabilities allow us to create fasteners ranging from small, intricate parts to large, complex components. Whether standard or custom-made to your specifications, we ensure each product meets the highest quality standards.

Coatings Applied to Our Products

Geomet

Geomet 321 is a high-performance, aluminum-grey coating designed to provide superior anti-rust protection for steel, cast iron, and other ferrous metal parts. Unlike Geomet 500, the primary distinction lies in the added lubrication in the mixture. This inorganic coating, made from thin zinc and aluminum plates, also incorporates PTFE, ensuring excellent protection without the risk of hydrogen embrittlement. Applied using non-embrittling cold immersion or spray techniques, Geomet 321 delivers reliable corrosion resistance.

Black Zinc

Our nuts and bolts are electroplated with a zinc flash coating and black chrome passivation, providing a sleek black zinc finish. This coating not only offers superior corrosion resistance but is also ideal for applications where color coding or aesthetic appeal is essential for identification purposes.

Zinc Flake

Our zinc flake coatings, applied through efficient dip-and-spin or spray techniques and cured by heating, offer excellent corrosion protection for fasteners. With a base of zinc flakes and a small percentage of aluminum, these coatings provide superior coverage and dimensional control. Widely used in the automotive sector, coatings like Geomet achieve over 600 hours of salt spray resistance, while also ensuring safe coating for high-tensile fasteners due to the absence of hydrogen embrittlement.

Hot Dip Spun Galvanizing

Hot-dip spun galvanized zinc is one of the most effective and cost-efficient coatings for iron and steel fasteners, offering outstanding corrosion resistance. Unlike electroplated zinc coatings, hot-dip finishes are rougher and dull in appearance, but the thicker layer of zinc—typically 50 microns (µm)—provides excellent protection, especially in harsh environments. This process involves dipping fasteners into molten zinc, followed by centrifuge spinning to ensure an even coat and removal of excess zinc. Because of the coating thickness, fasteners with thread diameters under M10 are typically not galvanized.

Electroplated-Zinc Coating

This zinc coating is applied to metallic parts to provide enhanced rust and corrosion protection, while also improving the visual appearance. The zinc layer can be applied through electrolytic or mechanical processes, offering a durable shield against environmental elements. Typically, the coating is free from hexavalent chromium (CRVI), giving it a shiny silver finish. However, other finishes can be tailored to meet specific requirements, offering flexibility in both protection and aesthetics.

Black Oxide

Black oxide, gun barrel blue, and blackening all refer to the same surface conversion process, where fasteners are immersed in a bath of sodium hydroxide, nitrates, and nitrites at 140°C. This treatment converts the surface of the steel into magnetite (Fe₃O₄), providing moderate corrosion resistance and a sleek black finish that reduces light reflection. While the coating offers only mild protection on its own, it is often combined with oil or wax to improve its durability. The main advantage of black oxide is its thin, uniform coating, which makes it ideal for applications that demand close tolerances.

Self Finish

Fasteners with a plain uncoated finish are often referred to as 'Black' or 'Self-Color' finish. These fasteners are typically oil-quenched, leaving a thin layer of oil residue on the surface that offers minimal corrosion protection. While they don't have any additional coatings, their natural finish is suitable for applications where aesthetic appearance or extra protective layers aren't critical.

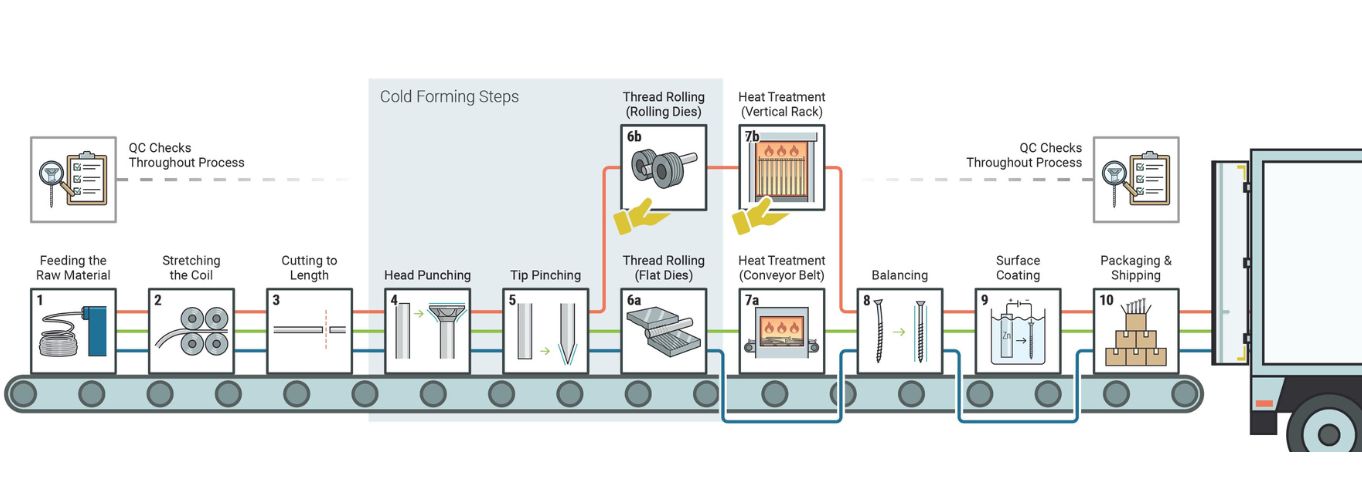

Our Manufacturing Process

Industry We Serve

Why Choose Us?

Quality Product

We are ISO 9001:2015 certified, ensuring the highest standards in fastener production. With our advanced production facility, in-depth industry expertise, and skilled team, we deliver high-performance, durable fasteners.

Customer Support

Our team of seasoned professionals is dedicated to delivering fast, customized solutions with a strong focus on customer satisfaction. We maintain open communication channels, ensuring your needs are met promptly and effectively.

Timely Delivery

Leveraging advanced technologies and high-performance manufacturing units, we specialize in delivering customized products faster than expected. Our trusted logistics partners play a crucial role in ensuring that your industrial hardware needs are met on time.

Quality Packaging

We believe that high-quality products are only possible through excellence at every stage of production. Our well-equipped packaging unit ensures that each product is carefully packed to prevent damage and is dispatched

What people saying about us

Request For Quote

Ready to secure top-quality fasteners for your needs? Contact us today for a no-obligation quote on our premium range of high-tensile fasteners. We’re here to provide you with exactly what you need at the right price.

Get In Touch…

For more information. Please fill the form.

47+ Years Manufacturing Experience

47+ Years Manufacturing Experience